The end of the industrial society?

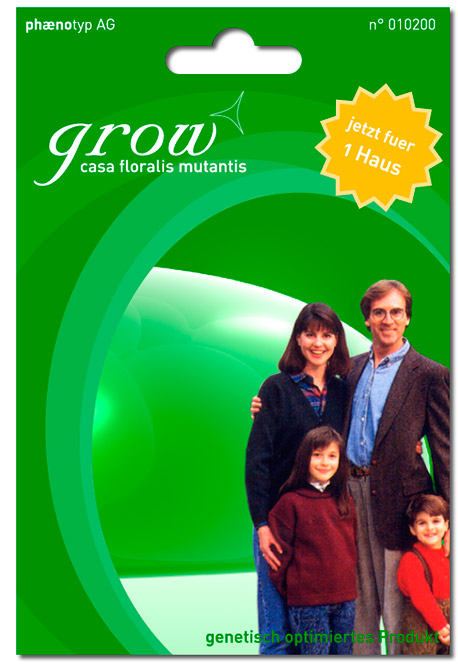

How is our society going to evolve? How are we going to produce in the year 2040? With the project “grow” we developed a vision in 2001. To breed plants in order for them to replace machine-made products. Our inspiration is a species of ants, which no longer builds their nests but inhabits a house of self-growing mushroom weaves.

The concept is simple: changing genetic information or transgenic combinations of several plants, which then influence appearance and characteristics. Living products like furniture, lamps or buildings are built that way. Supporting products like the breeding ground or injections are used to modify the plant while growing. Industrial production is replaced with organic breeding.

This changes the relationship between the user and the product entirely. The user himself becomes the producer, becomes his own supplier, who merely receives a construction plan in form of a seed. A new symbiosis develops with the product and the whole cycle of life because the plants stay alive and require continuous care. When thought to the close it shows that this concept would have various impacts on our consumption and the industrial society. The replacement of central industrial production and distribution with de-central, individual creation would have broad impacts on our economical and social self-concept.

Is this merely our mind playing a game, a utopia? By no means. It is basically about the immanent contradiction of innovation and sustainability. Several concepts and scenarios, such as the increasing awareness of environmental concern and fading resources, show parallels to “grow”.

In order to optimise the input of resources bionics take their guidelines for technical construction of their building structures from nature or organic growth. The growth of products in accordance to their static load is virtually displayed by using simulation processes such as the SKO (Soft Kill Option).

images: Stefan Biller, HS Magdeburg 2012; cradle-to-cradle®, EPEA; www.epea.com; 3D-printer envisiontec perfactory

The cradle-to-cradle-concept even goes a step further and gives an alternative to products that you simply throw away. Inspired by nature this old product is not just waste but resource. This cycle requires a change of industrial production and distribution because used products return to the producer. This might mean that one no longer buys a product but simply leases it or that the product is entirely replaced by a service or a completely different solution.

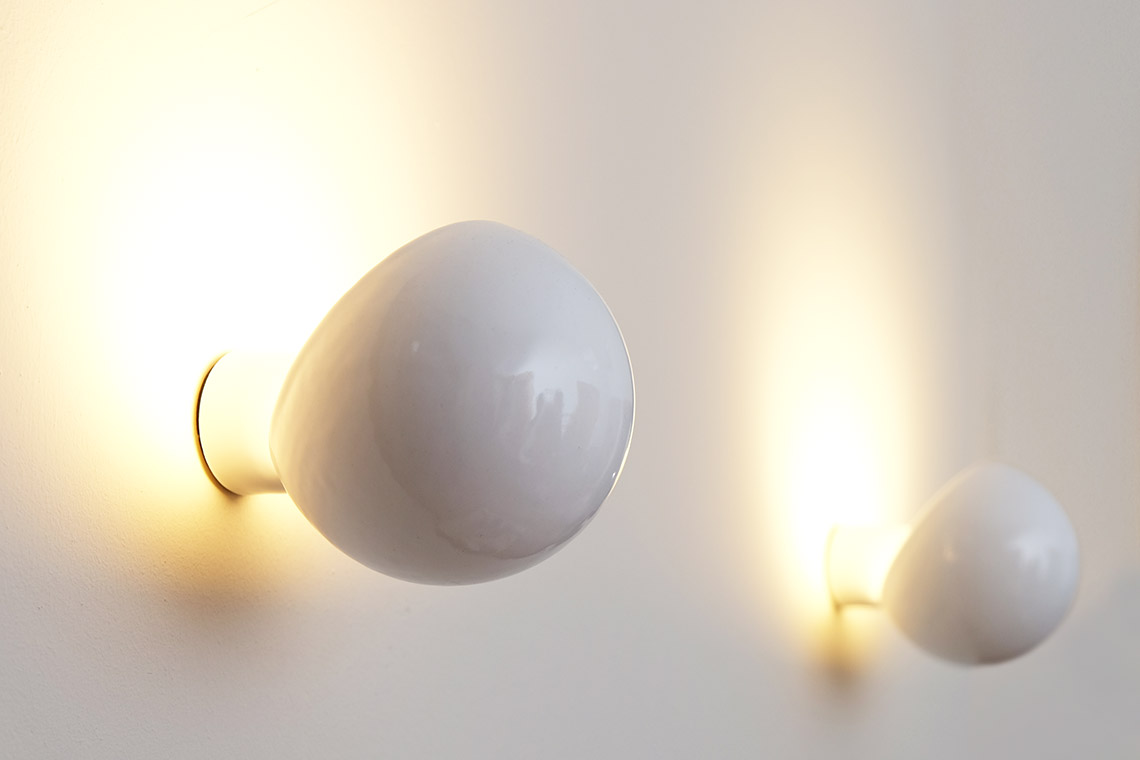

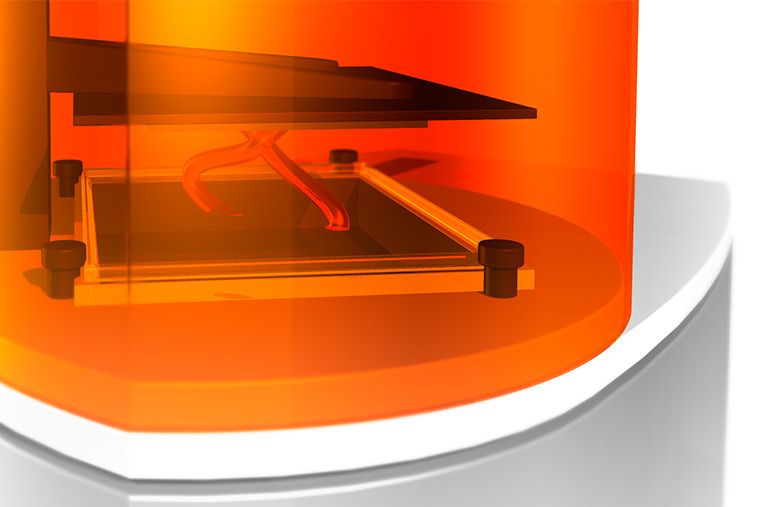

Also trends like globalisation und urbanisation lead to opposite movements such as rather using regional products, the self-making and self-supplying is becoming the new big thing. Today there are already 3D-printers, which make it possible to print simple products at home. Without expensive tools but individually fitted with optimal use of material. Since some time we are working on products for everyday use made from 3D printed porcelain, such as ceramic lights which are completed by a 3D printed wall fixation and standard bulbs and fittings.

A similar approach to self-production is "urban farming": humans do not rely on globalised supply any longer but grow their own vegetables on roofs and uncultivated land.

If in future products are no longer bought but leased instead, the consumer simply needs construction plans (or seeds) and becomes the producer himself, how will the producers’ role change? Is the producer going to be more of the curator of possible options? In what way is an idea going to be rated in the future? The beginning is visible – now this opportunity is to be used positively for the industrial base and its future.